Top 5 Common CIPP Installation Issues and Solutions

Cured-in-place pipe (CIPP) installation is a widely used method for trenchless pipe rehabilitation. However, like any construction process, it comes with its set of challenges. Understanding common issues and their solutions can help ensure a successful installation and long-lasting results.

Understanding CIPP Installation

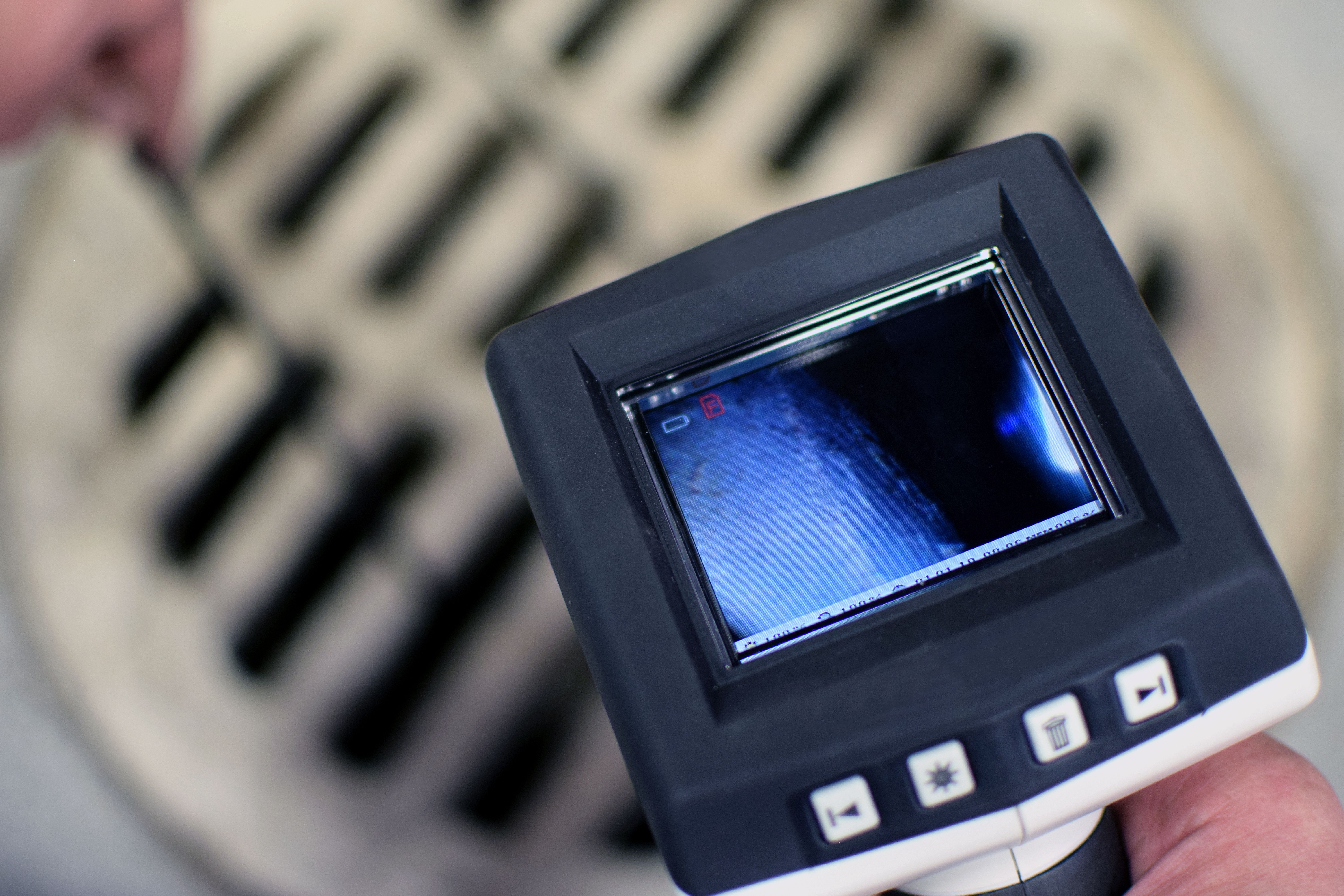

CIPP is a method used to repair existing pipelines without the need for excavation. This process involves inserting a resin-saturated felt tube into the damaged pipe, which is then cured to form a new, strong pipe within the old one. Despite its benefits, certain issues can arise during installation.

Issue 1: Incomplete Curing

One of the most common issues in CIPP installation is incomplete curing of the resin. This can lead to weak spots and potential failures. The primary cause is often insufficient heat or UV light exposure during the curing process.

Solution: Ensure that the curing process is monitored closely. Use the appropriate amount of heat or UV light for the specific resin being used, and follow the manufacturer's instructions meticulously.

Issue 2: Wrinkling of the Liner

Wrinkling occurs when the liner does not properly conform to the host pipe's shape. This can lead to flow restrictions and structural weaknesses.

Solution: To prevent this, ensure that the liner is correctly sized for the pipe and that it is installed under consistent pressure. Proper calibration can help in achieving the right fit.

Issue 3: Resin Leakage

Resin leakage can occur if there is a breach in the liner or improper sealing at the ends. This can cause contamination and reduce the structural integrity of the installation.

Solution: Use high-quality materials and ensure that all seams and ends are properly sealed. Regular inspections during the curing process can catch potential leaks early.

Issue 4: Host Pipe Condition

The condition of the host pipe can significantly affect the outcome of a CIPP installation. If the existing pipe is too deteriorated, it may not support the new liner.

Solution: Conduct a thorough inspection of the host pipe before installation. If necessary, prepare the pipe by cleaning or repairing major defects before proceeding with CIPP.

Issue 5: Inadequate Flow Capacity

After installation, some systems may experience reduced flow capacity due to incorrect sizing or liner thickness.

Solution: Proper planning and engineering are crucial. Ensure that the liner's thickness and diameter are suitable for the pipe's intended use. Collaborate with experienced engineers to design the installation for optimal flow.

By addressing these common issues, CIPP installations can be made more reliable and durable. With proper planning, monitoring, and execution, this method can provide a cost-effective and efficient solution for pipe rehabilitation.